Information Abstract:

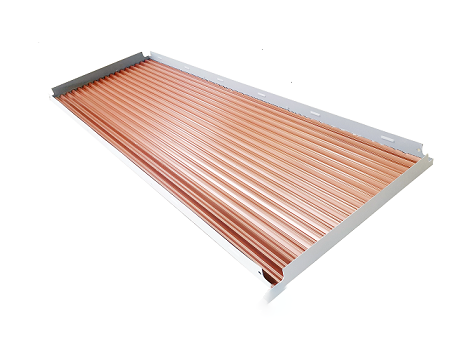

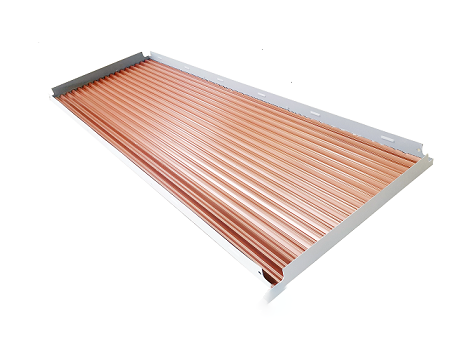

Aluminum corrugated board is an all-aluminum alloy composite board with a corrugated core sandwiched between the panel and the bottom plate. It is a product with advanced technology and newly developed technology. It retains the advantages of honeycomb aluminum plate and improves the disadvantages of aluminum-plastic composite plate,...

Kaimai aluminum corrugated composite board specifications

aluminum corrugated composite boardThe board is an all-aluminum alloy composite board with a corrugated core sandwiched between the panel and the bottom plate. It is a product with advanced technology and newly developed technology, which retains the advantages of honeycomb aluminum plate, improves the shortcomings of aluminum-plastic composite plate, and has a wide range of applications. Color, plate thickness, surface treatment process, size, etc. can be customized according to customer needs. Scope of application: office buildings, corridors, stations, factories, hospitals, clubs, banks, shopping malls, exhibition halls, etc.

aluminum corrugated composite boardConstruction process:

1. Measurement and setting out

1) The installation position line of the support frame is accurately bounced into the main structure according to the axis and elevation line on the main structure according to the design requirements.

2) All embedded parts shall be punched out and their dimensions shall be re-measured.

3) When measuring the line, the distribution error should be controlled, not the error accumulation.

4) The measurement and setting-out shall be carried out under the condition that the wind force is not more than level 4. After setting out, it should be checked in time to ensure the verticality of the curtain wall and the correctness of the column position.

2. Install the connection piece

Weld the fixed connector and the embedded parts on the main structure. When the embedded iron piece is not buried on the main body structure, the expansion bolt and the connecting iron piece can be drilled and fixed on the main body structure.

3. Install the skeleton

1) According to the position of the bullet line, use welding or bolts to accurately fix the anti-rust column on the connector. During installation, the elevation and centerline position should be checked at any time. For the large area, high wall aluminum curtain wall skeleton column, must be measured with measuring instruments and line drop, and its position is corrected to ensure that the vertical rod of the skeleton is straight and flat. The elevation deviation of column installation shall not be greater than 3mm, the front and rear deviation of shaft shall not be greater than 2mm, the left and right deviation shall not be greater than 3mm; The elevation deviation of two adjacent columns shall not be greater than 3mm, the maximum elevation deviation of the same layer column shall not be greater than 5mm, and the deviation of two adjacent erection distance shall not be greater than 2mm.

2) The connectors and gaskets at both ends of the beam should be installed at the predetermined position of the column, and should be installed firmly, and the horizontal deviation of the beam should not be greater than 1mm. Elevation deviation of the same floor: when the curtain wall width is less than or equal to 35 m, it should not be greater than 5 ㎜; When the curtain wall width is greater than 35, m time exceeds 7 ㎜.

4、安装铝板

Measuring and setting out

The aluminum corrugated board is fixed on the steel frame with rivets or bolts one by one according to the construction drawing. Between the plate and the plate left seam 10~15 ㎜, in order to adjust the installation error. Installation

aluminum corrugated composite boardWhen, the left and right up and down deviation shall not be greater than 1.5 ㎜.

5. Treatment of plate seam

Clean with detergent

aluminum corrugated boardAnd the surface of the frame, the sealing strip or the weatherproof rubber strip should be placed in the gap between the aluminum plates immediately, and the silicone weather-resistant sealant and other materials should be injected. The glue should be filled with no gaps or bubbles.

6. Curtain wall closure treatment

Metal plates may be used to seal the ends and keels of the wallboard.

7. Deformation joint processing

The treatment of deformation joints must first meet the needs of building expansion and settlement, and at the same time achieve the decorative effect. Heterosexual gold plate and neoprene belt systems can be commonly used.

8. Clean the board surface

Remove the gummed paper of the board surface and clean the board surface.

责任编辑:凯麦aluminum corrugated composite board厂家

Labels for this article:

Aluminum corrugated composite board specifications, aluminum corrugated board installation, exterior wall aluminum curtain wall, Camai aluminum corrugated board manufacturers

Copyright (Kaimai metal ceiling aluminum curtain wall) reproduced please indicate the source

National Service Hotline

National Service Hotline