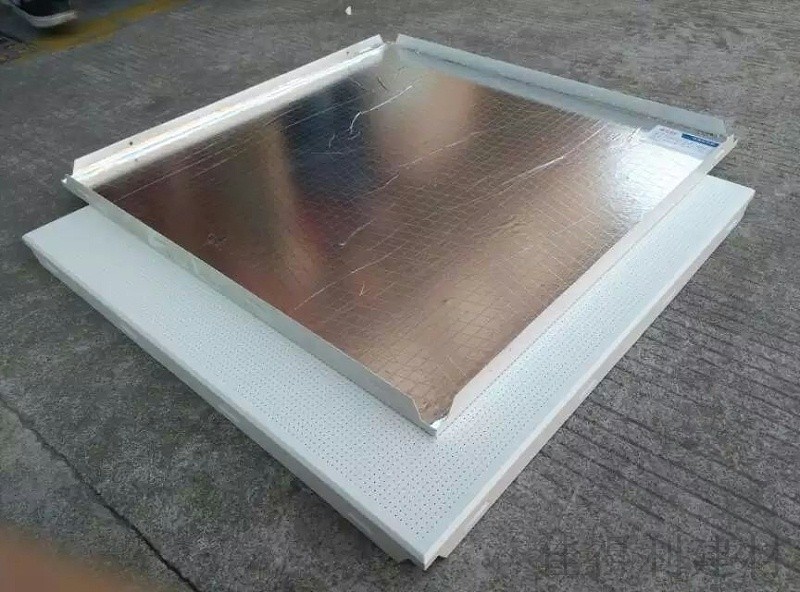

Kaimai aluminum composite panel manufacturer Kaimai fire-proof grade A aluminum composite panel The exterior wall and interior wall of the earliest architectural decoration are mostly aluminum-plastic panels. Due to poor fire resistance, Del Company has developed fire-proof grade A aluminum composite panels and fire-proof grade B aluminum-plastic panels, which are widely used in decoration and curtain wall industries due to their good fire resistance. With low economic cost, optional color diversity, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality, it is quickly favored by people. The unique performance of aluminum composite panel itself determines its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, display stands, purification and dustproof engineering. It belongs to a new type of building decoration material. The material is easy to process aluminum-plastic plate, and the weight per square meter is only about 3.5-5.5kg, so it can reduce the harm caused by earthquake disaster and is easy to handle. Its superior constructability can complete various shapes of cutting, cutting, edge planing, bending into arc shape and right angle with simple woodworking tools. It can cooperate with designers to make various changes, and the installation is simple and quick to reduce the construction cost. Excellent fireproof performance in the middle of the aluminum-plastic board is a flame retardant material PE plastic core material, both sides are extremely difficult to burn aluminum layer. Therefore, it is a safe fireproof material that meets the fire-resistant needs of building regulations. Impact resistance Strong impact resistance, high toughness, bending does not damage the topcoat, strong impact resistance, in the area of large sand will not appear due to sand damage. Super weather resistance due to the use of KYNAR-500 as the base material of PVDF fluorocarbon paint, weather resistance has a unique advantage, whether in the hot sun or cold wind and snow are not damaged in the beautiful appearance, up to 20 years do not fade. The coating is uniform and colorful. After chemical treatment and the application of Henkel\'s skin film technology, the adhesion between the paint and the aluminum-plastic plate is uniform and the colors are diverse, allowing you to choose more space and show your personalization. Easy maintenance of aluminum-plastic panels, in the resistance to pollution has been significantly improved. China\'s urban pollution is more serious, the use of a few years after the need for maintenance and cleaning, due to good self-cleaning, only with a neutral cleaning agent and water can be, after cleaning the plate permanent as new. Easy processing aluminum plate is easy to process, forming a good material. It is a good product for the pursuit of efficiency and time, which can shorten the construction period and reduce the cost. Aluminum plastic plate can be cutting, cutting, slotting, band sawing, drilling, processing countersunk, can also be cold bending, cold folding, cold rolling, riveting, screw connection or adhesive bonding. Manager Huang -13074271912

National Service Hotline

National Service Hotline

Advisory Hotline