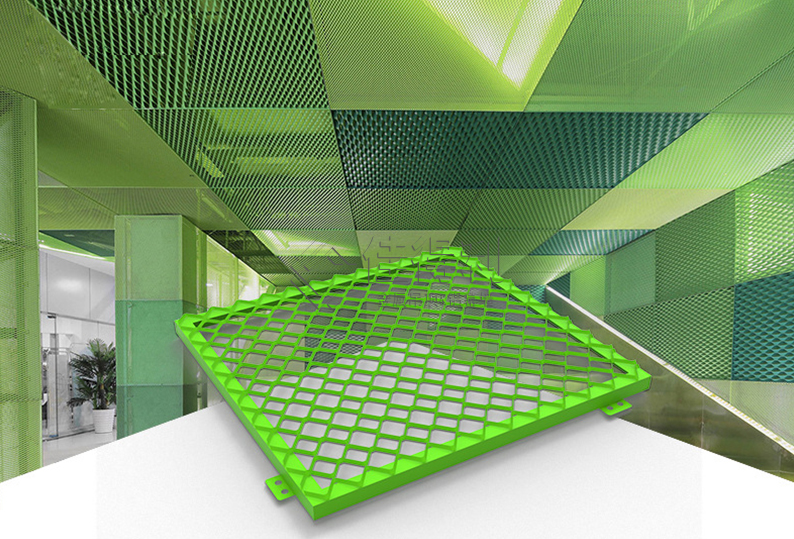

关于Punched wire-drawn aluminum veneerAttention points for ceiling installation and construction

Today, the small editor of Kaimai Building Materials will talk about the process flow and operation technology of punching and drawing net aluminum veneer ceiling. It is divided into the following three points!

一、Punched wire-drawn aluminum veneerPreparation for suspended ceiling construction

The construction of various pipes, equipment and ventilation pipes in the ceiling, fire alarm system and fire sprinkler system has been completed, and has passed the acceptance procedure for handover and concealed works. Piping systems require test water and pressure to complete. Complete the ceiling layout before the construction of the large drawing, and determine the location of the ventilation openings and various openings. Prepare operating platform racks or movable racks for construction. Before large-scale construction of metal ceiling, samples or samples should be made first. Blocks and fixing methods shall be tested and qualified prior to large area construction.

Construction tools: chainsaw, toothless saw, hand saw, pistol drill, screwdriver, square ruler, steel ruler, steel level ruler.

二:Punched wire-drawn aluminum veneerKey Points of Ceiling Construction

Construction line: according to the aluminum ceiling of punching wire mesh, the vertical and horizontal layout line of component materials, the contour line of more complex parts, and the elevation line of the ceiling; at the same time, identify and mark the ceiling lifting point.

Ceiling fastening treatment: According to the design requirements, use metal expansion bolts or pins to fix the ceiling connection, or directly fix the steel bars, galvanized wires and flat iron suspension parts.

The combination and combination of aluminum monomers: local monomers and monomers, units and units, as part of the rhythmic pattern on the top of the aluminum monomer, should be assembled on the ground as much as possible if necessary. Then the suspension is carried out according to the design requirements. In order to ensure the connection between the various components, according to the relevant technical requirements of woodworking, use fasteners, adhesives, rattan and use wood or iron reinforcement.

Construction process of 3. punching and drawing net aluminum veneer ceiling

1. Fixed position of bullet line measurement

Use a level to copy the horizontal points on the corners of each surface (column) in the room (if the wall is long, a few points should be appropriately copied in the middle), and pop up the horizontal line (the distance between the horizontal line is generally 500, from the height of the horizontal line to the design height of the ceiling, the horizontal line is sprayed along the wall (column) as a powder line, which is the lower skin line of the suspended ceiling punching pull plate aluminum plate. At the same time, according to the ceiling plan, the location of the main keel pops up on the concrete roof. The main keel shall be separated from the center of the ceiling to both sides, with a maximum distance of 1000; and the fixed point of the suspender shall be marked. The fixed point of the suspender is 900~1000. If the fixed point of the beam and pipe is greater than the design and adjustment requirements, the fixed point of the suspender shall be added.

2. Fixed pendant

采用膨胀螺栓固定吊杆。您可以使用吊杆。悬架杆可采用冷拔钢条和圆形钢条,但应采用机械拉直的圆形钢条。其中一端是用l30*30*3的角码焊接的。(角码的孔径应根据吊杆和膨胀螺栓的直径确定)另一端可以用来为大于100;的线杆拉线,或者购买完成的线杆。焊接。完成的爆炸应该是防锈处理。吊杆用膨胀螺栓固定在地板上。冲击锤是用来打孔的。孔径应略大于膨胀螺栓的直径。

3. Light steel keel installation

The light steel keel should be hung on the boom (if the ceiling is low, this process can be omitted, and the next process can be carried out directly). Generally use 38 light steel keels, spacing 900~1000 light steel keels should be installed in parallel rooms and arched at the same time. The height of the arch is from 1/200 to 1/300 of the span of the room. The cantilever part of the light steel keel should not be greater than 300; otherwise, the boom should be increased. The joint length of the main keel shall be butted, and the butt joints of adjacent keels shall be staggered. The light steel keel shall be basically flat after hanging. Ceilings with a span of more than 15 meters should be placed on the main keel, and a large keel should be added every 15 meters, and the main keel should be welded firmly and vertically.

4. Spring installation: use a boom to connect the light steel keel (if the ceiling is low, the spring can be directly installed on the boom to omit the process), with a spacing of 900 to 1000; The spring is stuck on the boom.

5、Punched wire-drawn aluminum veneerThe design drawings below the primary and secondary bone components require the primary and secondary bones of the perforated aluminum laminate to be pre-installed.

6、Punched wire-drawn aluminum veneerInstallation: The pre-installed punched and pulled aluminum veneer ceiling is hung with a hook in the main bone hole, and the entire gate ceiling is connected and adjusted to level.

Aluminum veneer profile has a highly respected position in architectural decoration materials. Kaimai Xiaobian also recommends that you use aluminum veneer curtain wall when decorating exterior walls. I hope today's sharing will help you!

Responsible editor: Kaimai aluminum veneer curtain wall manufacturer-Huang Liping 13074271912

This article labels: aluminum veneer curtain wall, fluorocarbon aluminum veneer, curtain wall aluminum veneer, wood grain aluminum veneer, aluminum veneer manufacturer

Copyright (Kaimai metal ceiling aluminum curtain wall) reproduced please indicate the source

本文标签: Aluminum veneer curtain wall Fluorocarbon aluminum veneer curtain wall aluminum veneer wood grain aluminum veneer Aluminum veneer manufacturers

National Service Hotline

National Service Hotline

Advisory Hotline